Product Description

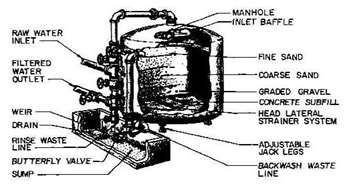

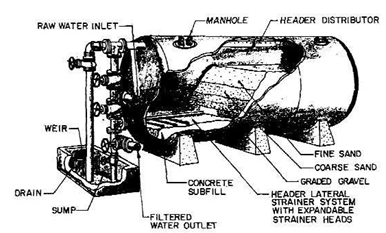

A typical pressure sand filter consists of a pressure vessel - this could be either vertical or horizontal-fitted with a set of frontal pipe work and valves, graded sand supported by layers of graded under bed consisting of pebbles and silex, a top distributor to distribute the incoming water uniformly throughout the cross section of the filter, and an under drain system to collect filtered water. Pressure Sand Filter is also available in ASME and IEI Good Engineering practices.MOC is MS, MSRL and MSEP. Frontal pipe works are available in MS, MSRL. Fig 1 shows the arrangement of a vertical pressure sand filter.

Working Principle

In pressure sand filter raw water flows down wards through the filter bed and as the suspended matter- which has usually been treated by addition of a coagulant like alum- is retained on the sand surface and between the sand grains immediately below the surface. There is steady rise in the loss of head as the filtration process continues and the flow reduces once the pressure drop across the filter is excessive.

Fig-1: Vertical Pressure Sand Filter

Fig-2: Horizontal Pressure Sand Filter

The filter is now taken out of service and cleaning of the filter is effected by flow reversal. To assist in cleaning the bed, the backwash operation is often preceded by air agitation through the under drain system. The process of air scouring agitates the sand with a scrubbing action, which loosens the intercepted particles. The filter is now ready to be put back into service.