RECYLE OF INDUSTRIAL AND RESIDENTIAL WASTEWATER, SEWAGE, SULLAGE

INTRODUCTION:

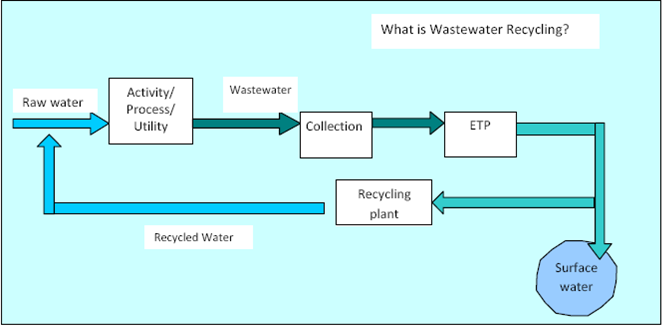

Optimum use of existing water resources is today's need to cope up with decreasing rain falls, increasing population and pollution load; growing urbanization and Industrialization and rapidly depleting water resources. This could be efficiently done by increasing cycles of use of water for various activities before it could be discharged into natural sources. By doing this we will help reduce the load on existing resources and save the cost for providing additional fresh water supply to cities, towns and industrial estates.

The conventional methods of treatment of wastewater could not achieve the quality of water required for reuse. It is made possible by advanced Membrane separation processes like micro filtration, ultra filtration, nano filtration, reverse osmosis and membrane bio-reactors. Nowadays technologies are available to enable recycle of water from industrial effluents, domestic sullage and urban sewage and recovering of as much as 85 - 90% water ‑ moving to idea of zero liquid discharge.

Currently treated water is mostly used for low end uses like toilet flushing, gardening and floor washing. But now Membrane technology is successfully applied to obtain high quality water for the high end uses like Boiler feed, cooling water makeup and also for process water depending on the extent of treatment provided. Membrane Technologies are pressure driven processes used for removal of suspended solids and/ or dissolved impurities present in water, wastewater and process liquids. The wastewater recycle treatment plants mainly involves treatment with Ultra filtration (UF) followed by Reverse Osmosis (RO). They are used as post treatment to existing treatment plants employing biological and/ or physico-chemical treatment or polisher to fresh water supply to achieve high purity water for process use.

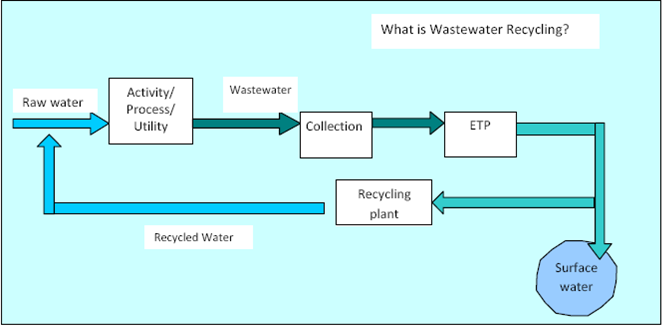

A typical recycling plant for industrial effluent with UF-RO:

All Industries use fresh water for its various processes and washing and cleaning. The utilized water finds its way into drain and collected for treatment and is called as effluent. The Quantity and quality of the effluent varies widely from industry to industry.

The major contaminants in any Effluent are suspended solids, oil & grease, organic matter (BOD and COD) and Dissolved Solids. The effluent is passed through series of treatment process to remove these contaminants. The oil & grease, coarse and Settleable solids are removed in primary treatment and organic matters (COD & BOD) in secondary biological treatment; to meet the effluent discharge norms provided by the pollution Control Boards.

The above treatment does not reduce the dissolved inorganic salts and to some extent organic compounds. Up to certain limit they are not harmful to natural resources hence could be discharged without removal but while reusing they creates problems such as scaling of pipelines, corrosion, biological contamination and fouling, reaction with other chemicals and changing the quality of product from processes etc. Hence, they need to be removed before reusing and this is where UF/ RO plays a vital role. RO Membrane with Ultra Filtration (UF) have made a mark in recovering water for reuse from industrial effluents or treated municipal sewage while maintaining the ease of treatment and operation.

ULTRA FILTRATION (UF):

Ultra filtration is a tangential flow, low pressure driven membrane process that separates particles on the basis of their molecular size. Pore diameters of Ultra filtration membranes are in the range of 10 to 200 A (0.02 to 0.001 micron). It removes of virtually all-particulate matter, suspended solids, bacteria, viruses and pyrogenic species, colloidal material (non-reactive silica, iron, aluminum etc.) and high molecular weight organics. UF also reduces TOC, Colour components, SDI etc. hence it is used to improve downstream RO performance with respect to flux rates, recoveries and reduced maintenance, cleaning frequencies and associated costs.

REVERSE OSMOSIS:

Reverse Osmosis is a high pressure membrane process that rejects practically all undissolved and dissolved impurities present in water, wastewater and process liquids. The process employs a semi permeable membrane that allows selective removal of impurities.

RO membrane processes are already well established in the production of high purity water for pharma industry as well as for manufacture of semiconductors. Now they offer tremendous opportunities in the treatment of water, wastewater and process liquids and played a vital role in treatment of effluents not only for recovery of water but also valuable raw material which can be reused in the process.

MULTIPLE – EFFECT EVAPORATOR:

In today's world, as demands on the industry increase to comply with more restrictive environmental legislations, zero liquid discharge (ZLD) has become an important concept in wastewater treatment. For years, Reverse Osmosis (RO) system has been used for ETP recycle applications. But, industries face problem of disposal of RO reject/ concentrate, which has high TDS value. This RO reject can be fed to multiple effect evaporator (MEE) where dissolved solids will be concentrated. Thus, we get condensate which has very low TDS and solid crystals that can be sent to landfill. Condensate from evaporator can be combined with RO permeate and can be reused as process water.

In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the previous one. Because the boiling point of water decreases as pressure decreases, the vapour boiled off in one vessel can be used to heat the water in the next vessel, and only the first vessel (at the highest pressure) requires an external source of heat such as fresh steam. In multiple effect evaporator, generally steam is used as the heating media.

Two most commonly used types of Evaporators for RO reject are:

A. Falling film evaporator:

In this type of evaporator, liquid flows downwards in the form of a film along with the vapours in parallel flow. It is ideally suited to heat sensitive non-salting and non-crystallizing solutions. In falling film evaporators, velocity of liquid through tubes is maintained below 1.5 m/s. In these evaporators sufficient wetting of the heating surface is very important for the heat economy and trouble free operation.

B. Forced circulation evaporator:

It is ideally used when the boiling of feed liquid on the heating surfaces is to be avoided due to the salting and fouling characteristics of the liquid. In forced circulation evaporator, velocity of liquid through tubes is maintained in the range of 2 m/s to 3 m/s. This liquid is partially evaporated when the pressure is reduced in the vapor-liquid separator to the corresponding boiling temperature. High-volume, low-head axial flow pumps are used for recirculating the crystal-laden slurry in the evaporator.

OTHER APPLICATIONS OF REUSING WASTEWATER FROM:

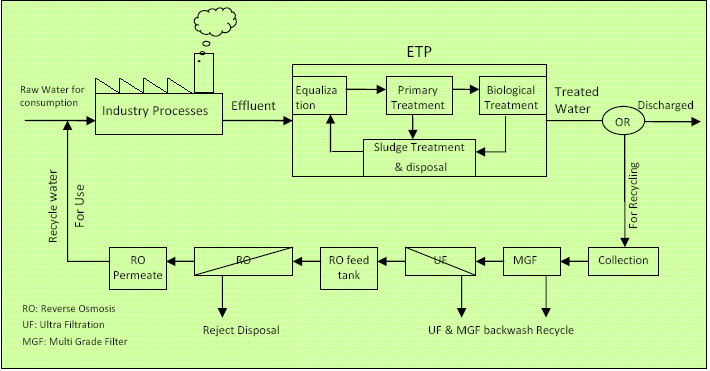

1. Residential/ Commercial Complexes:

The urban domestic sector consumes 80% of total water supplies. The wastewater collected from residential and commercial complexes is from bathing, washing, cleaning and toilet flushing and called as sewage. Apart from other contamination the Sewage wastewater contains high organic load and Human and/ or animal feces contamination and needs a biological treatment to reduce the organic load.

The typical flow schematic of sewage recycling plant is as follows:

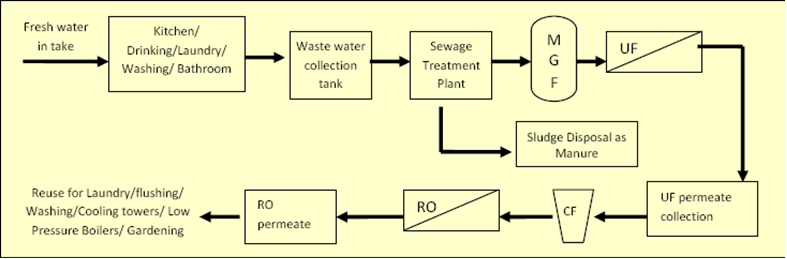

Sullage recycle

The wastewater from domestic sector can also be segregated; where the waste from bathroom, washing and kitchen is collected separately and is called as Sullage. The sullage is then treated by coagulation, filtration and disinfection, and then pumped to the overhead tank and could be supplied for toilet flushing and gardening, reducing the requirement of fresh water by 60%. The sullage recycle systems are ideal for residential colonies as well as hotels, hospitals and large institutions. Such systems would help reduce infrastructural costs on public water supply systems as well as avoid heavy losses of water through leakages during distribution through public supply pipelines. Thus segregation of waste stream could reduce the treatment and operating costs.

Ion Exchange India is under a process of developing suitable products for sullage recycling which is compact, economical and easy to implement.

2. Non organic wastewater like:

The wastewater generated from cooling tower blow down, Boiler blow down, DM regeneration effluent, Filter backwash, etc. contain contaminants like SS, TDS, alkalinity, hardness only. They do not contain much of organic compounds and therefore don't need biological treatment and can be recycled after pH correction & primary treatment.

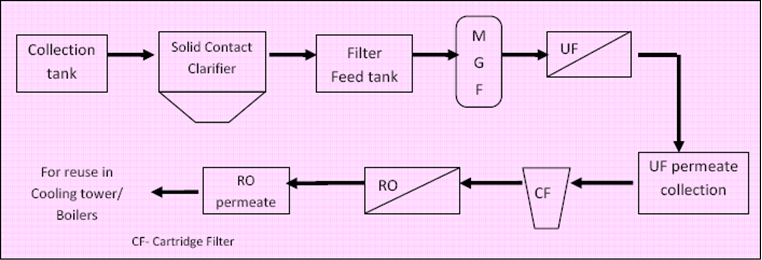

A typical flow schematic is as follows:

BENEFITS OF USING UF–RO TREATMENT FOR RECYCLING ARE AS FOLLOWS: